Case Studies

Estimation Of Flow Characteristics For A Marine Propeller

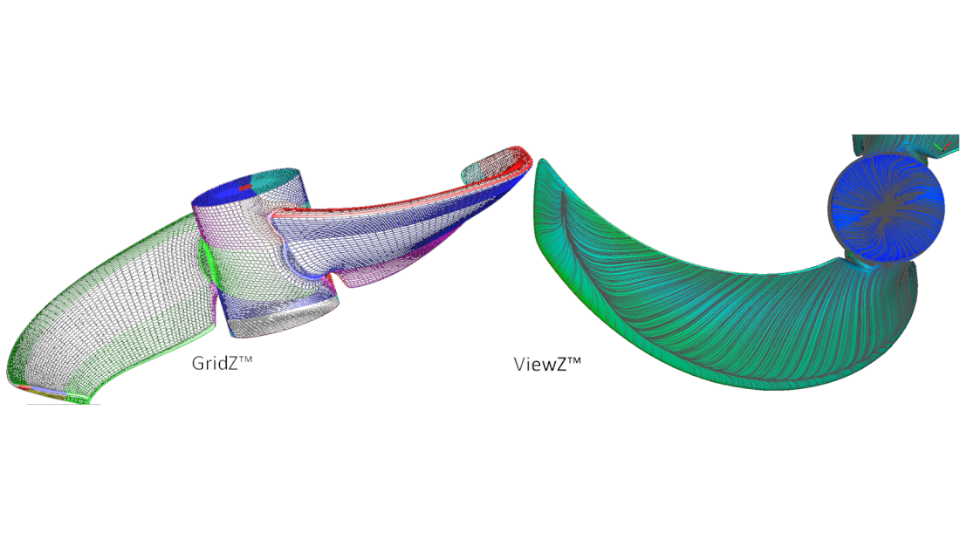

Our customer is one of the foremost designers and manufacturers of pumps, propellers and other fluid machinery equipment. They are in process of redesign of marine propeller for increase in performance and wanted to engage Indian vendor for high end turbo machinery simulations. The current propeller is two bladed and the blades are is highly twisted from hub to tip, increasing the complexity of mesh generation.

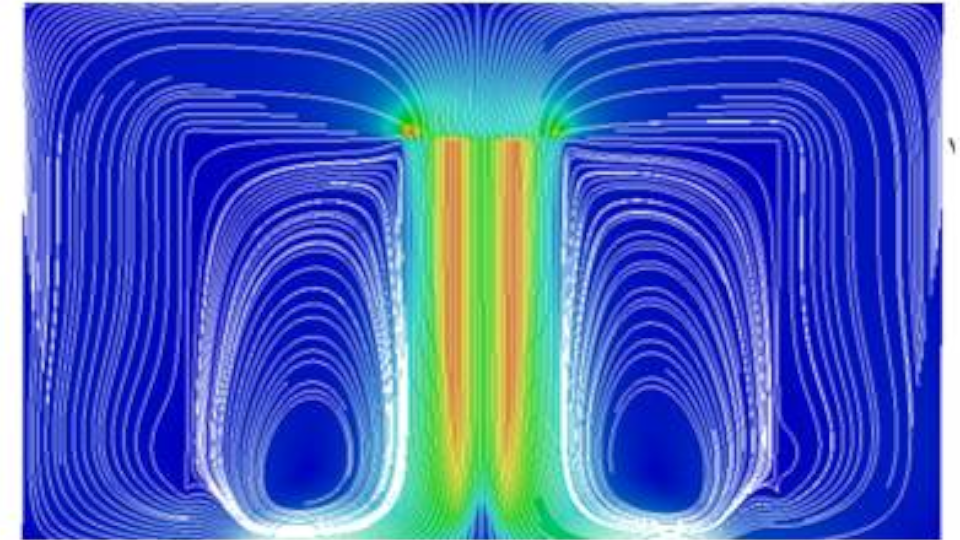

The design parameters affecting the performance of the propellers are no of blades, its sectional profile, distribution of chord and twist, bladesetting angle, and these needed to be changed in case of any performance issues. Since the requirement was to capture the flow physics very accurately including the separations if any Zeus Numerix decided to use the structured multi-block grid (shown below). Mesh had 372 blocks and 1.28 million mesh points. To capture the boundary layer first cell thickness from the surface was kept at 50 microns.

Simulation revealed that there is a separation line on the suction surface of the propeller. Even with the change in RPM the surface streamline behavior remained unchanged. Observation was also made that simulation fails to capture the separation if CFD uses laminar flow or wrong turbulence model. Customer was given suggestions to mitigate the separation by changing the section profile of the blade keeping the hub and maximum diameter fixed.